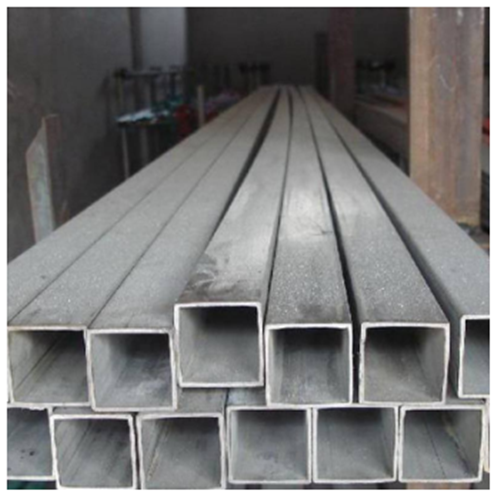

Stainless steel polishing machine equipped with polishing wheel. When polishing, the polishing wheel tells the rotation, the high temperature generated by the friction between the surface of the stainless steel square tube and the polishing wheel improves the plasticity of the tube surface, and under the action of the polishing force, the matrix surface produces plastic deformation, the raised part is depressed, and flows to the concave, so that the surface roughness is reduced. In addition, the chemical composition of the polishing tube and the surrounding medium react chemically with the polished metal during the polishing process, greatly enhancing the polishing effect.

Polishing can also be divided into coarse sand, fine sand and light three. Coarse sand using 180#- 320# thousand impeller on the surface of the tube after processing the surface effect. Fine sand is the surface effect of processing the pipe surface with 320#- 600# thousand impeller. The mirror is polished by the combination of impeller, hemp wheel and cloth wheel, so that the surface of the tube can obtain the mirror bright effect.

The advantage of this way of polishing is that the equipment is relatively simple, easy to operate, and does not require chemical AIDS. The disadvantage is that the seamless optical tube cannot be polished inside, and improper disposal is easy to produce scratches.

Due to the microscopic inconsistencies of the surface of the stainless steel square tube, the microscopic protruding part of the material in the chemical medium is preferentially dissolved than the concave part during chemical polishing, so as to obtain a flat picture. The advantage of this method is that there is no need for complex equipment, the steel pipe can be polished internally, and a large number of steel pipes can be polished at the same time, and the efficiency is high. The core problem of chemical polishing is the configuration of polishing fluid. The surface roughness obtained by chemical polishing is generally tens of microns.

hui li yu steel

hui li yu steel